Guest Post by Endimo Analytics

The time taken to complete a traditional soccer game from start to finish is almost always more than the 90 minutes ticking down on the clock. Besides the two 45-minute halves, there is a 15-minute pause at half time, as well as the “extra time” added at the end of each game by the referees.

This extra time represents the sum of all the pauses and delays that occurred throughout the match, and while there are specific rules about how much time must be added for each player substitution, it is ultimately up to the referee to determine how many extra minutes will be played before the final whistle sounds.

But make no mistake, the wasted time in soccer – even with a referee adding a few minutes at the end – cannot all be recovered.

Soccer’s Wasted Time: By the Numbers

A recent study carried out by UEFA determined that the average Champion’s League match lasted 94 minutes and forty-seven seconds (excluding the 15-minute half time). However, it turns out that only 61:06 is devoted to actual play time with the ball in-bounds. This means that for a full 33:41, the ball was not in play. In other words, for almost a third of the time a fan is watching, there is no action.

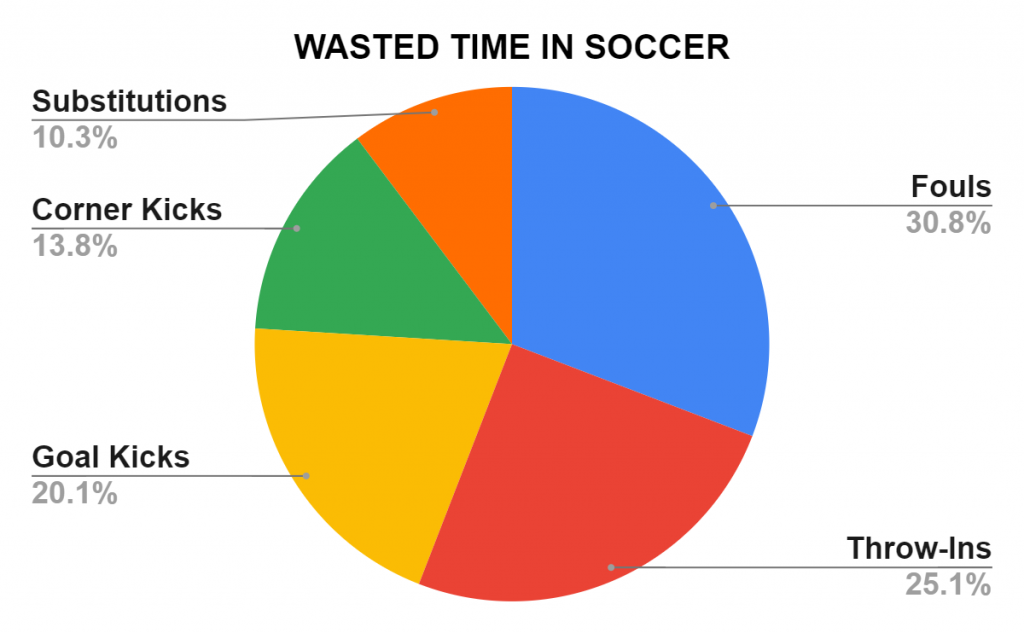

The UEFA study also determined which events caused the most wasted time. Of the 34 minutes of paralyzed play, the balance was as follows: by fouls (8:51), by throw-ins (7:02), by goal kicks (5:46), by corner kicks (3:57) and by substitutions (2:57).

Wasted time for fouls can add up. In one example from the 2018 World Cup in Russia, the Brazillian footballer Neymar spent a full 14 minutes on the ground! And wasted time isn’t just an interesting statistic, it also costs the league money and threatens the integrity of the sport. As a result, soccer leagues around the world are intent on finding ways to reduce the intentional wasting of time that occurs in soccer matches.

Besides eliminating some of the unsportsmanlike behavior we often see, the result of a reduction in wasted time is a more entertaining product for the fans, and greater returns for the team owners.

So how does this connect to lead time in inventory management?

Lead Times Explained

Generally speaking, a lead time is the amount of time that passes from the start of a process until its conclusion.

In MRO (Maintenance, Repair and Operations) supply chain management, lead time is defined as the period between the moment when the decision to generate a purchase request is made, and the moment when the product is available for use. Longer lead times can lead to a supply delay, and in the inventory management process, anything that can negatively affect lead time can result in lower profits over the long term.

There are number of different types of lead time, including:

- Production lead time

- Manufacturing lead time

- Customer lead time

- Material lead time

Efficient inventory management processes (supported by a robust and well-integrated inventory management software) is enormously important. In the same way that soccer leagues around the world try to reduce the time it takes to deliver exciting play to their fans by reducing or eliminating non-play time, those in the supply chain management game try to increase their own customer satisfaction by lowering the amount of time it takes to deliver their products.

Having a well-designed lead time formula (supported by a lead time calculator) makes calculating lead time easier. Knowledge is power, and with more information, organizations can shorten lead time with the result being a more smooth supply chain journey for parts and essential materials.

Managing Lead Times in MRO Supply Chain Management

There are two important factors related to managing lead times in the MRO supply chain.

So how does this connect to lead time in mro inventory management?

- The current replenishment time

- The variability of the delivery lead time

Just like the way soccer clubs try to find ways to increase the amount of time the fans enjoy watching the ball in play, lead times in business should be reviewed regularly to identify biases affecting service to end users, or costs related to oversupply or long-anticipated purchases.

One way to do that is to more closely examine historical purchase orders and receipts. These can be analyzed and processed to estimate the time of each segment that makes up the lead time of an item. This exercise is the starting point to identify stoppages that increase delivery times. So what are the equivalent of fouls, throw-ins, and corner kicks that extend lead times?

There are several problems commonly associated with the supply chain that have a negative impact on delivery times. They are:

- Lack of demand forecast

- Delay in the approval of purchase orders

- Lack of follow-up

- Product availability issues

- Poor planning routes

- And many more

Unfortunately, despite great advances in the supply chain, delivery times continue to be a critical point. This is why integrating technology and inventory management software into the supply chain is essential. It is the best way to reduce lead time.

With the right technology, businesses all over the world and across a variety of industries will have better visibility, as well as an increased ability to calculate lead time and control all the stages involved in delivering an item.

The Benefits of Lower Lead Times

Amazon, which you might say is the “Manchester City” of electronic commerce, is a leader in customer satisfaction. Anyone who has received a package from hundreds of miles away in a matter of hours knows just how good they are.

Thanks to the technology and speed of its service, we’ve all begun to get used to their speed. Despite this, Amazon continues to research and develop new technologies all the time to meet customer demand and reduce the amount of time it takes for a product to reach its customer. The use of drones is one example of how Amazon plans to improve their already highly optimized delivery times in the near future.

In the MRO supply chain, a reduction in lead time variability translates into a reduction in safety stock, and therefore a reduction in the value of inventory sitting in the warehouse. The lower the value of unused inventory, the more cash on hand a company has to achieve its goals.

By increasing lead time accuracy, companies can better define optimal inventory replenishment parameters to meet required service levels, and this is especially important in Asset Intensive Organizations.

Finally, sharing demand forecasts and establishing commercial agreements with international and local suppliers is another effective tool to reduce delivery times. Doing this helps organizations constantly maintain a sufficient stock of medium-fast moving items.

Soccer and Supply Chains: The Big Difference

As we mentioned at the top of this article, FIFA regulations allow referees to make up some of the lost time at the end of each match. However, there is no equivalent in the business world. In the MRO supply chain, time lost due to lead time issues cannot be recovered.

To remain competitive, it is not enough to simply boost profitability through higher productivity or by lowering costs. It is also extremely important to fully satisfy customers. A focus on lead time management will help us achieve this goal.

Do you want to know how your organization can reduce lead times through the latest inventory optimization tools? Xtivity can help.

About the Author: Endimo Analytics is a partner of Xtivity, based in Peru and serving the South American market. Endimo is a consulting firm specializing in MRO Supply Chain Management to help clients transform business processes, optimize master data, and implement comprehensive MRO solutions.