Optimize Parts Inventory Across

Maintenance, Repair and Operations (MRO) management and spare parts inventory optimization play critical roles in keeping equipment assets up and running. Current supply chain upheaval has fueled inflation, increased costs and supplier lead times – placing supply at risk. Asset intensive companies need new ways to predict and manage their parts supply chain.

Targeting Your Parts Inventory

MRO Health Check provides a cost-friendly deep analysis of your transactional data and current practices to uncover high-value MRO inventory optimization opportunities. Learn More

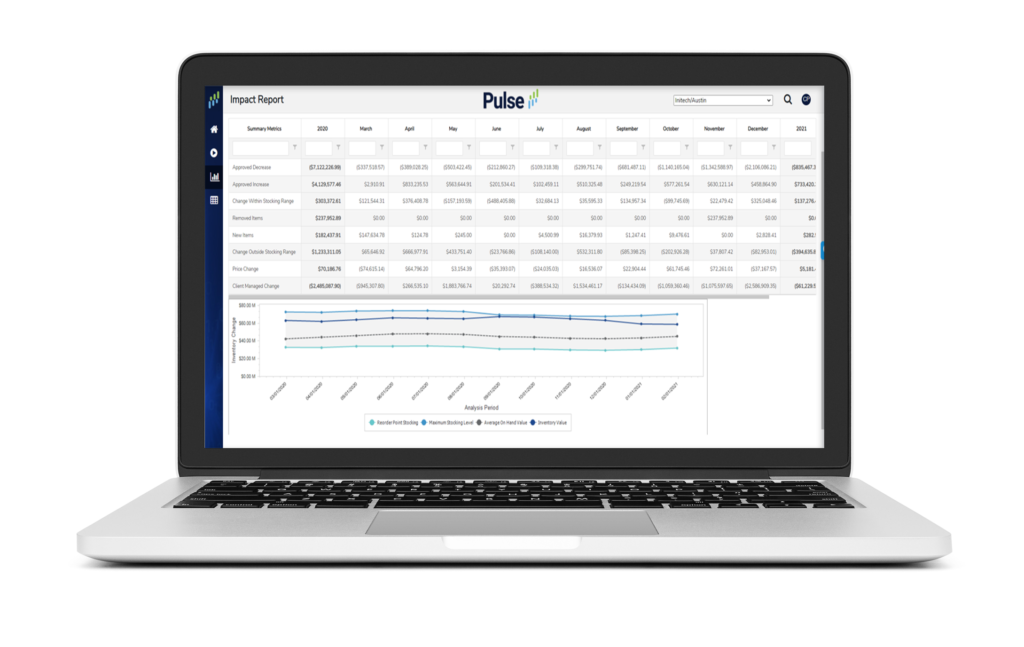

With data intelligence from Pulse, you can optimize parts inventory and improve lead-time management, reducing working capital and associated carry-costs. Learn More

Address specific challenges in your supply chain with Direct Charge Analysis, Parts Criticality Assignment and Master Data Cleansing and Enhancement. Learn More

Outcomes Achieved By Our Clients

Data-Driven Insights in 3-5 Weeks

- Understand how your MRO supply chain is performing and discover ways to improve it

- Increase reliability, drive operational efficiencies and reallocate working capital

- Provide fact-based answers to questions on downtime and asset availability

- Identify how your MRO supply chain can be leveraged for competitive advantage

Quantify Potential Value in Your Inventory with an MRO Health Check

Contact us to get a sample MRO Health Check report, with information on how it works and the key deliverables you can expect.

The ROI was lightning fast. Pulse continues to provide a low cost, effective solution to optimize inventory; a concern that’s rarely addressed in organizations. Inventory Management Specialist

Our Platform

Proven, cloud-based decision support software for MRO parts inventory management and optimization.

- Based on prescriptive analytics, ML algorithms, business rules and years of human experience

- Leverages data from your ERP/EAM to expose issues, trends and insights

- Optimizes parts replenishment through ordering and lead-time recommendations

- Provides productivity tools, standard and user-built reporting and KPI visualizations

Quickly Address Specific Challenges in Your Supply Chain

I thought optimization meant less inventory. It really means the right inventory. – Plant Engineering Manager

Our services team can enhance your MRO Parts Catalogue data and ensure your inventory is aligned with your business by conducting Direct Charge Analysis and Parts Criticality Assignment. We’ve helped mining companies to decrease MRO costs, increase productivity and mitigate the risk of increasing supplier lead times with improved MRO performance visibility and workflow automation.

Enhance your MRO catalogue, to include frequently purchased MRO goods through description-based direct charge. Gain visibility into your MRO off-catalogue spend to leverage all spend to source goods and support demand planning.

Trusted by Industry Leaders