Balancing the Scales: How Part Criticality Powers Smarter Inventory Decisions

Few challenges across the asset management landscape are as critical—or as complex—as balancing cost and risk.

Few challenges across the asset management landscape are as critical—or as complex—as balancing cost and risk.

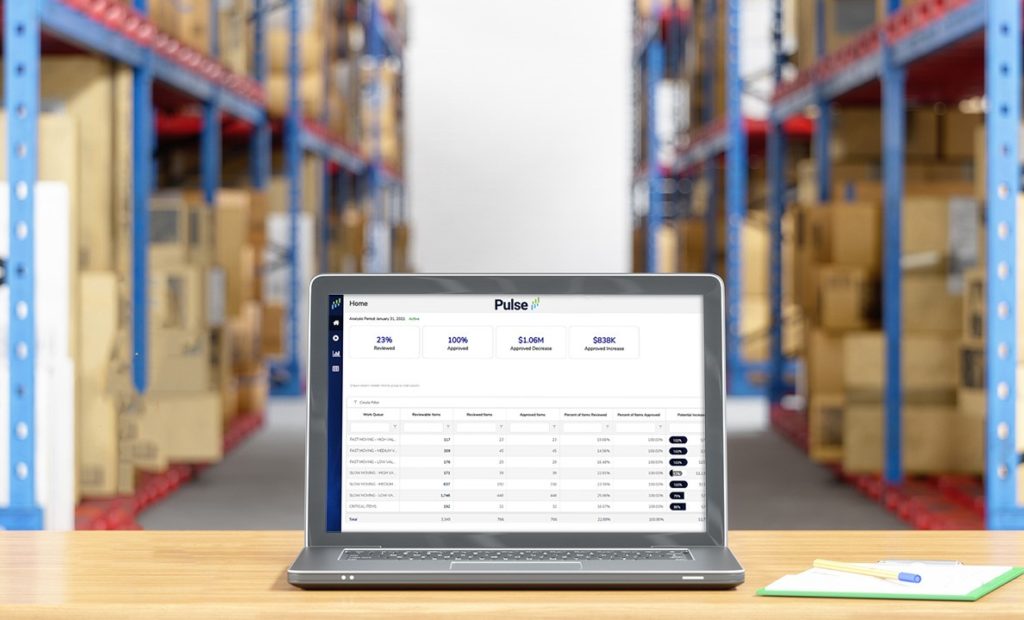

With the rising use of analytics and internal business mandates encouraging data-driven decisions, the quality of MRO data has become more critical than ever.

Having a robust parts criticality program can result in less unplanned downtime, better maintenance schedule adherence and an overall improvement in asset health.

As part of reliability and supply chain improvement, there’s huge potential for efficiency and productivity gains with proactive optimization of spare parts inventory.

How to strike the right balance with your MRO parts inventory, to meet shifting supply chain demands.

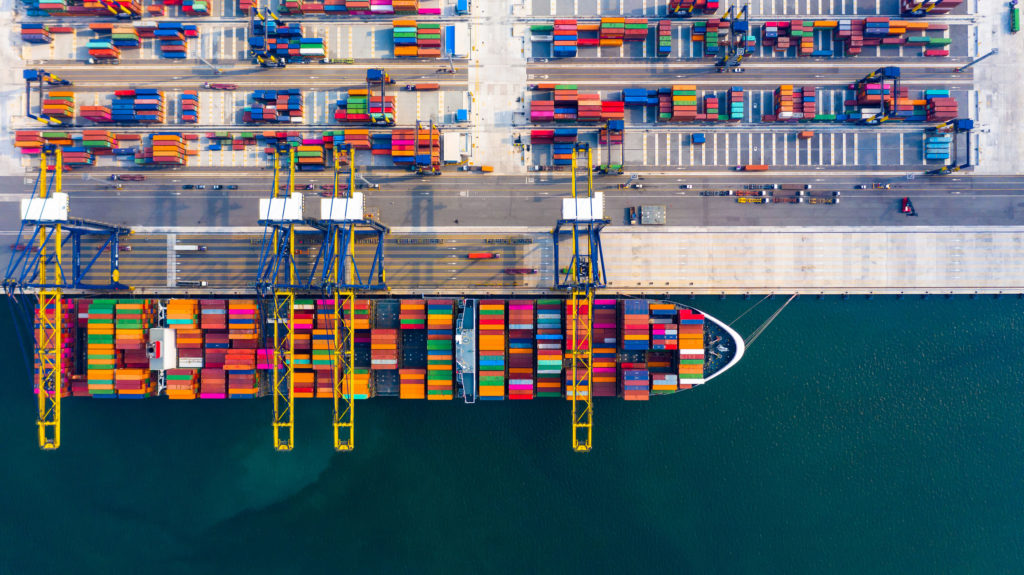

Finding new ways to predict and manage their parts inventory has become imperative for mining companies striving to minimize the cost and disruption of an uncertain supply chain.

Today’s data-driven solutions can help optimize the MRO supply chain and inform your Enterprise Asset Management decisions.

To mitigate supply chain risk, we need to get back to the basics and increase resilience with intelligence technologies that can help us monitor, predict and get in front of change.

5 Key considerations to future proof and remove risk from your indirect supply chain.

In most industries, there are clear risks associated with excess inventory.